Products Catalog

- Bearings

- Petroleum Machinery Bearings

-

Precision Bearings

- High precision angular contact ball bearings

- High-speed sealed angular contact ball bearings

- Double-direction angular contact thrust ball bearings

- High-speed angular contact thrust ball bearings

- Ball screw support bearings

- Hybrid Ceramic Ball Bearings

- Cylindrical Roller Bearings

- Precision tapered roller bearings

- Turbo-charger bearing

- YRT bearings

- Four point contact ball bearings

- Thin section bearings

- Cross roller bearings

- Dental bearings

- Slewing Bearings

- Wind Turbine Bearings

- Bearings For Rolling Mills

- Bearings For Rail Transportation

- Automotive Bearings

- Hydrodynamic Bearings

- One-way Bearings

- Spherical Roller Bearings

- Standard Ball Bearings

- Taper Roller Bearings

- Spindles

- Precision Bearing Instruments

- Bearing Parts Measuring Instruments

- Finished Bearing Measuring Instruments

- Air-floating And Dense-ball Spindles

- Induction Heaters

- Degaussing Equipment

- Bearing Testing Machines

- Bearing Manufacturing Machines

- Bearing Relevant Materials

- ZYS Bearing Steel

- Bearing Ball Series Products

- Bearing Antirust lubricating Oil And Grease

- Bearing Cage Materials

- Abrasion-resistant Materials

Turbo-charger bearing

Description

As the only state-level comprehensive research institute in China's bearing industry, ZYS can design and manufacture ball bearings, roller bearings and precision bearings to perform in a wide range of applications. Full range of bearings can be found with free CAD download, short lead times, competitive price.

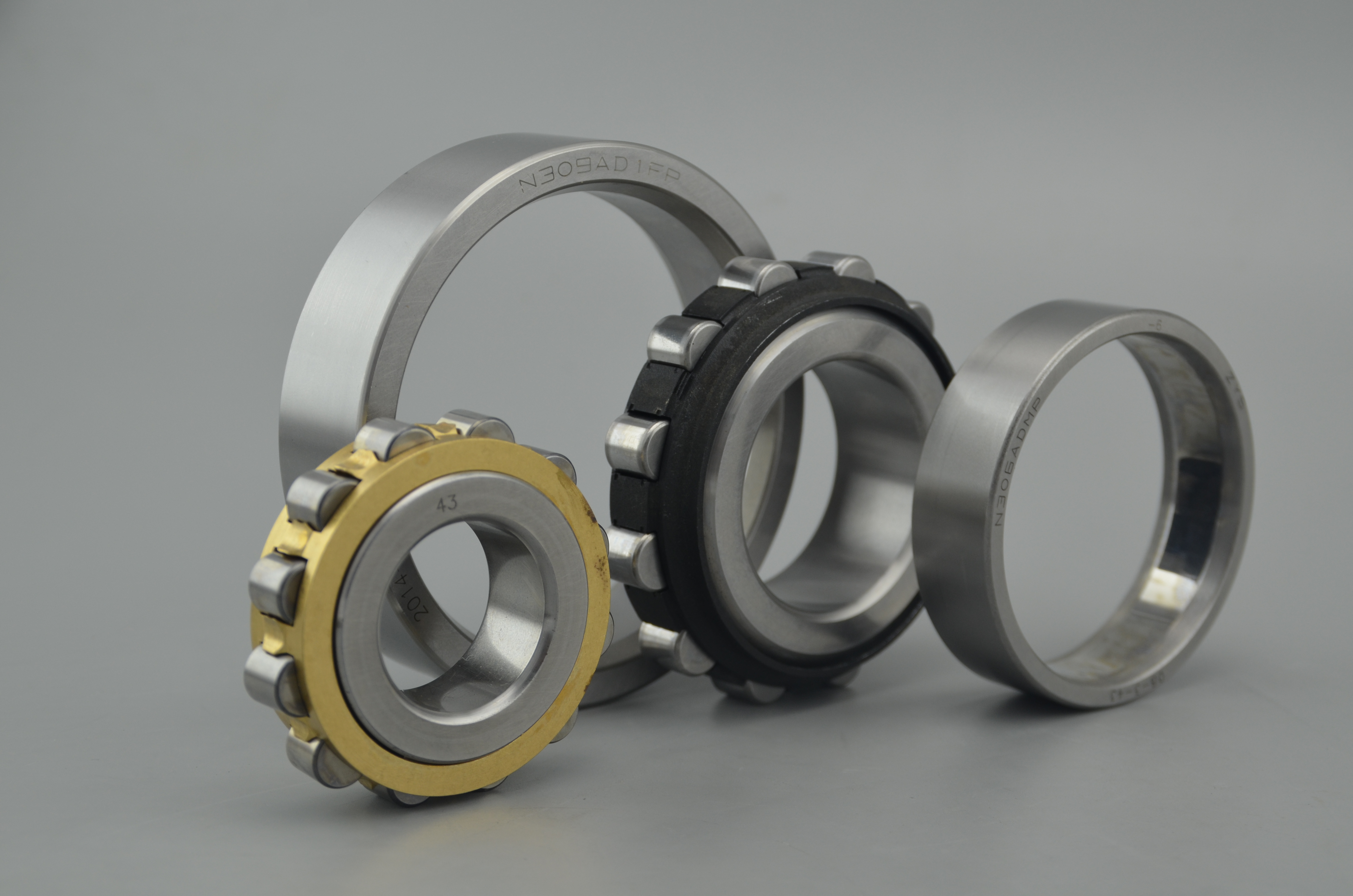

Turbo-charger bearing

ZYS turbocharger bearings refer to deep groove ball bearings, cylindrical roller bearings, angular contact ball bearings and four-point contact ball bearings. Angular contact ball bearings are used in pairs or matched with four-point contact ball bearing, then can support radial and axial combined loads. Deep groove ball bearings and cylindrical roller bearings mainly support radial load.We usually use alloy steel cage with special surface treatment to meet the requirements for higher speed and greater load. Application of turbo bearings: Turbochargers are commonly found in automobiles, and are actually an air compressor that compresses air to increase the amount of intake air. It uses the inertial impulsive force of the exhaust gas discharged by the engine to push the turbine in the turbine chamber, and the turbine drives the coaxial impeller. The impeller pressurizes the air sent from the air cleaner pipe to make it pressurized into the cylinder. When the engine speed increases, the discharge speed of exhaust gas and the turbine speed also increase synchronously, and the impeller compresses more air into the cylinder;and the increase in air pressure and density can burn more fuel, correspondingly increasing the amount of fuel and adjusting the engine speed and then increasing the output power of the engine. As a key moving part of the turbocharger, the structure of the turbo bearing is related to the reliability and durability of the turbine. Turbocharger bearings are mainly divided into two categories, one is floating bearings, and the other is ball bearings. The floating bearing is a ring that is sleeved on the shaft. There is a gap between the ring and the shaft and between the ring and the bearing seat to form a double oil film. The ring floats between the shaft and the bearing seat. Generally, the inner layer gap is about 0.05mm, and the outer layer gap is about 0.1mm. The bearing wall thickness is about 3.0-4.5mm, made of tin-lead bronze alloy, and the bearing surface is plated with a layer of lead-tin alloy or metal indium with a thickness of about 0.005-0.008mm. When the supercharger is working, the bearing rotates between the shaft and the bearing seat. The ball bearing is to install the ball on the turbine shaft to replace the position of the oil in the floating bearing. The advantage of the ball bearing is that the friction force is smaller, and it can effectively control the dynamics of the turbine shaft.