ZYS provides high quality bearing products and professional bearing solutions for users in the fields of machine tool, wind power, metallurgy, automobile and rail transportation, construction machinery, etc. ZYS can perform batch production of various bearing products with inner diameter of 0.6mm to outer diameter of 6.8m. In addition to bearings, ZYS can also offer high-speed spindles, precision bearing instruments, bearing testing machines, bearing manufacturing machines and bearing parts.

ZYS precision angular contact ball bearings consist of high-precision angular contact bearings (standard series),super high-speed angular contact ball bearings,high-speed sealed angular contact ball bearings and high-speed spindle bearings.

In the metallurgical industry, the working environment of rolling mills, continuous casting machine or converters is really harsh. These conditions require bearings to withstand the harsh effects of heavy load, high temperature, dust and water. In order to meet the requirements of metallurgical industry, ZYS R & D teamhas developed bearings products with high quality, high precision and long service life and also can offer the bearing solutions for manufacturers in the metallurgical industry.

ZYS large-size heavy duty precision bearings are manufactured in our second industry park,which covers 133,333㎡ with total investment of 438 million RMB.

The inner ring,outer ring and rolling elements of bearing under normal working conditions are made of high carbon chromium bearing steel.To meet the special requirements,such as super high speed,wear-resisting,low temperature rising,long life and high reliability etc.,it’s suggested to use hybrid ceramic ball bearings.

ZYS has been committed to the research and development of bearings for rail transportation for a long time to meet the increasing requirements for rail transportation,such as higher speed,load,reliability and etc.

ZYS plays an leading role in aerospace bearing industry of China,We has successfully accomplished the bearing assemblies for “Dong fang hong” series man-made satellite,manned spacecraft series from “Shenzhou Ⅰ” to “Shenzhou Ⅹ”,“Chang’E” lunar exploration program,successful docking from “Shenzhou Ⅷ” and “Shenzhou Ⅸ” to Tiangong target aircraft.

ZYS automobile bearings include tapered roller bearings,cylindrical roller bearings,deep groove ball bearings and angular contact ball bearings,among which clutch bearings and the hub bearings units of the first,second and third generation are mainly used to gear box,axles,transmission system and other parts of all kinds of automobiles.We have conducted thorough research on wheel hub bearings,clutch release bearing,constant velocity cardan joint,gear box bearings and etc

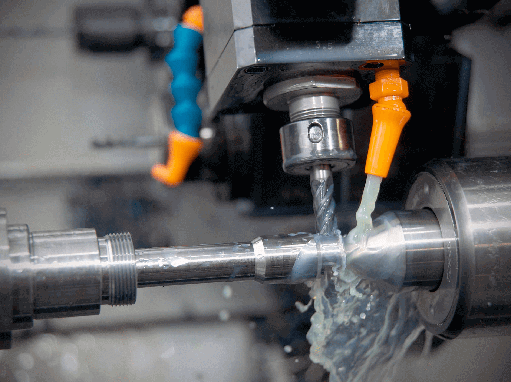

ZYS can supply batch production of various bearing manufacturing equipments,like CNC cutting equipments and automatic production line for bearing rings,automatic grinder,superfinishing machine,precision cold rolling machine for bearing rings,semi-automatic multi-purpose grinder for miniature ball bearing rings and other precision manufacturing equipments for bearing.

Besides all kinds of bearing products,bearing measuring machines are also our main products,which have been exported to India,Iran,Romania,Brazil and many other countries.Our main measuring machines include the instruments for measuring the dimension accuracy,roundness,profile and roughness of bearing parts,the instruments for inspecting bearing performance and other instruments used to automatically inspect and control various parameters during manufacturing process.These instruments are widely used in bearing workshops,inspection stations,measuring room and assembly factories.

ZYS has conducted in-depth research on bearing testing technology and reliability theory of all kinds of bearings,engaging in the development and manufacture of bearing testing equipments and undertaking the simulation testing,life testing and other performance tests for all kinds of bearings.We can also develop and manufacture the simulation testing machines in full-automatic control for the bearings used in various machineries (aviation,spaceflight,railway,automobile,motorcycle,machine tool,motor,etc.)

Since 1958, ZYS has been committed to the research and development of “high-tech, precise, cutting-edge, specialized and special” bearings, and relevant products. Our products have been used for mining, metallurgy, wind turbine generator, machine tool, machinery, medical treatment, automobile, rail transport, etc.

Maintaining ball screw bearings is crucial for ensuring optimal performance, longevity, and reliability in industrial applications. Proper maintenance practices can help prevent premature wear, reduce downtime, and extend the service life of the bearings. Here are some key maintenance requirements for ball screw bearings in industrial settings:1. Regular Lubrication Frequency: Ball screw bearings require regular lubrication to reduce friction, prevent wear, and maintain smooth operation. The frequency of lubrication depends on factors such as operating conditions, load, speed, and the type of lubricant used. Lubricant Selection: Choose the appropriate lubricant recommended by the bearing manufacturer based on factors such as temperature range, speed, load, and environmental conditions. Improper lubrication can lead to premature wear and failure of the bearings. Proper Application: Ensure that the lubricant is applied correctly and in the right quantity to all contact surfaces of the ball screw bearings. Over-lubrication can be as detrimental as under-lubrication, leading to overheating and performance issues. 2. Monitoring and Inspection Regular Inspections: Perform routine visual inspections of the ball screw bearings to check for signs of wear, damage, or contamination. Look for abnormal noise, vibration, or irregularities in motion, which may indicate potential issues that require attention. Cleanliness: Keep the surrounding area clean to prevent the ingress of contaminants such as dust, debris, and moisture, which can accelerate wear and compromise the performance of the bearings. 3. Alignment and Installation Proper Installation: Ensure that the ball screw bearings are installed correctly and aligned according to the manufacturer's specifications. Improper installation can lead to misalignment, increased friction, and premature failure of the bearings. Alignment Checks: Periodically check the alignment of the ball screw bearings with the shaft and other components to ensure that they are operating within the specified tolerances. Misalignment can result in uneven wear and reduced efficiency. 4. Temperature and Environmental Conditions Temperature Control: Maintain the operating temperature within the recommended range to prevent overheating or cold-start issues that can affect the performance of the bearings. Environmental Protection: Shield the ball screw bearings from harsh environmental conditions such as moisture, humidity, and corrosive substances that can degrade the lubricant and lead to premature wear. 5. Replacement and Upkeep Scheduled Replacements: Plan for scheduled replacements of ball screw bearings based on the manufacturer's recommended maintenance intervals or signs of wear and degradation observed during inspections. Documentation: Keep detailed records of maintenance activities, including lubrication schedules, inspections, replacements, and any issues encountered. This information can help track the performance of the bearings and guide future maintenance efforts. By adhering to these maintenance requirements and practices, industrial operators can ensure the optimal performance and longevity of ball screw bearings in their machinery and equipment. Regular maintenance not only improves the efficiency and reliability of industrial processes but also helps prevent costly downtime and repairs associated with bearing failures.

2024-10-11 10:49:11 move

The maintenance of ball screw support bearings

2024-10-11 10:49:11Maintaining ball screw bearings is crucial for ensuring optimal performance, longevity, and reliability in industrial applications. Proper maintenance practices can help prevent premature wear, reduce downtime, and extend the service life of the bearings. Here are some key maintenance requirements for ball screw bearings in industrial settings:1. Regular Lubrication Frequency: Ball screw bearings require regular lubrication to reduce friction, prevent wear, and maintain smooth operation. The frequency of lubrication depends on factors such as operating conditions, load, speed, and the type of lubricant used. Lubricant Selection: Choose the appropriate lubricant recommended by the bearing manufacturer based on factors such as temperature range, speed, load, and environmental conditions. Improper lubrication can lead to premature wear and failure of the bearings. Proper Application: Ensure that the lubricant is applied correctly and in the right quantity to all contact surfaces of the ball screw bearings. Over-lubrication can be as detrimental as under-lubrication, leading to overheating and performance issues. 2. Monitoring and Inspection Regular Inspections: Perform routine visual inspections of the ball screw bearings to check for signs of wear, damage, or contamination. Look for abnormal noise, vibration, or irregularities in motion, which may indicate potential issues that require attention. Cleanliness: Keep the surrounding area clean to prevent the ingress of contaminants such as dust, debris, and moisture, which can accelerate wear and compromise the performance of the bearings. 3. Alignment and Installation Proper Installation: Ensure that the ball screw bearings are installed correctly and aligned according to the manufacturer's specifications. Improper installation can lead to misalignment, increased friction, and premature failure of the bearings. Alignment Checks: Periodically check the alignment of the ball screw bearings with the shaft and other components to ensure that they are operating within the specified tolerances. Misalignment can result in uneven wear and reduced efficiency. 4. Temperature and Environmental Conditions Temperature Control: Maintain the operating temperature within the recommended range to prevent overheating or cold-start issues that can affect the performance of the bearings. Environmental Protection: Shield the ball screw bearings from harsh environmental conditions such as moisture, humidity, and corrosive substances that can degrade the lubricant and lead to premature wear. 5. Replacement and Upkeep Scheduled Replacements: Plan for scheduled replacements of ball screw bearings based on the manufacturer's recommended maintenance intervals or signs of wear and degradation observed during inspections. Documentation: Keep detailed records of maintenance activities, including lubrication schedules, inspections, replacements, and any issues encountered. This information can help track the performance of the bearings and guide future maintenance efforts. By adhering to these maintenance requirements and practices, industrial operators can ensure the optimal performance and longevity of ball screw bearings in their machinery and equipment. Regular maintenance not only improves the efficiency and reliability of industrial processes but also helps prevent costly downtime and repairs associated with bearing failures.

move

Ball Screw Support Bearings: Enhancing Precision in Motion Control Systems

2024-10-08 10:30:13In the realm of motion control systems, precision is paramount. Whether it's in manufacturing, robotics, or aerospace, the ability to manipulate movement with accuracy and efficiency is a defining factor in the success of any application. Ball screw support bearings play a crucial role in achieving this precision, providing stability and smooth operation in high-load and high-speed scenarios.Understanding Ball Screw Support BearingsBall screw support bearings are specialized components designed to support the axial and radial loads that occur in ball screw applications. Ball screws are commonly used in various industrial machinery and automation systems to convert rotational motion into linear motion efficiently. However, the performance of a ball screw greatly depends on the support bearings that help to maintain its rigidity and accuracy.Key Features and Benefits Axial and Radial Support: Ball screw support bearings are engineered to provide both axial and radial support, ensuring the smooth and precise movement of the ball screw under heavy loads. High Rigidity: These bearings are designed to withstand high levels of axial and radial forces without compromising on rigidity, making them ideal for applications where stability is critical. Reduced Friction: By minimizing friction between the components, ball screw support bearings contribute to smoother operation and increased efficiency in motion control systems. Enhanced Precision: The combination of high rigidity and low friction results in enhanced precision, allowing for accurate positioning and repeatability in various industrial processes. Long Service Life: With proper maintenance and lubrication, ball screw support bearings can have a long service life, contributing to the overall reliability of the machinery they are installed in. Applications in Various Industries Manufacturing: In CNC machines and precision machining tools, ball screw support bearings play a vital role in achieving the accuracy required for complex manufacturing processes. Robotics: In robotic arms and automation systems, these bearings help in precise movement control, enabling robots to perform tasks with speed and accuracy. Aerospace: Ball screw support bearings are used in aerospace applications where precision and reliability are critical for the safe operation of aircraft and spacecraft. Considerations for Selection and MaintenanceWhen selecting ball screw support bearings for a specific application, factors such as load capacity, speed, rigidity, and operating environment must be taken into account. It is crucial to follow manufacturer recommendations for installation, lubrication, and maintenance to ensure optimal performance and longevity of the bearings.In conclusion, ball screw support bearings are indispensable components in motion control systems, enabling precise and reliable operation in a wide range of industrial applications. Their ability to handle high loads, provide rigidity, reduce friction, and enhance precision makes them essential for achieving efficiency and accuracy in modern machinery and automation systems. As technology continues to advance, the demand for higher precision and efficiency in motion control systems will only increase, further underscoring the importance of ball screw support bearings in the industrial landscape.

move

Using Bearings Without Lubrication: Is It Possible?

2024-09-25 15:02:21Bearings are crucial components in various machines and mechanisms, enabling smooth rotation and reducing friction between moving parts. Traditionally, bearings are lubricated to minimize wear and heat generation, ensuring their longevity and efficient operation. However, the question arises: Can bearings be used without lubrication?Understanding the Role of LubricationLubrication in bearings serves multiple key purposes:Reduction of Friction: Lubricants create a thin film between the moving parts, reducing direct contact and frictional resistance.Heat Dissipation: By reducing friction, lubricants help in dissipating heat generated during operation, preventing overheating and premature failure.Corrosion Prevention: Lubricants protect bearing surfaces from corrosion and wear, enhancing their lifespan.Noise Reduction: Proper lubrication can help dampen noise generated by the moving parts.Lubrication Methods for BearingsVarious lubrication methods are employed in bearings, including:Grease Lubrication: Grease is a common lubricant in bearings, offering good sealing properties and longevity.Oil Lubrication: Oil provides better heat dissipation and is often used in high-speed applications where continuous lubrication is required.Dry Lubrication: Some modern bearings are designed to operate without traditional lubrication, using solid lubricants or self-lubricating materials.Challenges of Using Bearings Without LubricationWhile it is technically feasible to operate bearings without traditional lubrication, several challenges must be considered:Increased Friction: Without lubrication, friction between bearing components can increase significantly, leading to accelerated wear and reduced efficiency.Heat Build-Up: Lack of lubrication impedes heat dissipation, potentially causing overheating and premature failure.Corrosion Risk: Unprotected bearing surfaces are more prone to corrosion and surface damage.Noise Generation: Operating bearings without lubrication can increase noise levels due to enhanced friction.Specialized Applications for Dry LubricationIn certain specialized applications where traditional lubrication is not feasible or practical, dry lubrication technologies are employed. These can include:Solid Lubricants: Bearings infused with solid lubricants like graphite or PTFE can operate effectively without traditional lubrication.Self-Lubricating Bearings: Some bearings are designed with self-lubricating properties, using materials that release lubricants during operation.Extreme Conditions: In environments where contamination or maintenance is a concern, dry lubrication methods can offer advantages.While it is possible to use bearings without traditional lubrication in certain cases, it is crucial to consider the specific requirements of the application. Lubrication plays a vital role in the performance and longevity of bearings, and alternative methods like dry lubrication should be chosen carefully based on the operating conditions.In conclusion, while bearings can technically operate without lubrication, it is generally recommended to use appropriate lubricants to ensure optimal performance and longevity. Proper maintenance and lubrication practices are essential in maximizing the efficiency and lifespan of bearings in various applications.

move