Home > crane-bearing

Crane Bearing

Related

"Crane Bearing"

Blog| What is four-point contact ball bearings |

The Four point contact ball bearings is a separate bearing, and it can also be said to be a set of angular contact ball bearings that can withstand axial loads in both directions. The inner and outer ring raceways are peach-shaped cross sections. When there is no load or pure radial load, the steel ball and the ferrule are in four-point contact, wh...

View Details

| Slewing Bearing Repairs for the Crane Industry |

This bearing style is widely used for crane bearinghttp://www.zysbearing.com/key-crane-bearing-6/rotation in boom, crawler, telescopic, and rough terrain cranes for heavy lifting applications due to its versatility, load carrying capability, maximum life under loading, and ease of refurbishment.zys also provides and services slewing ball bearings.O...

View Details

| ROAD EXPO. |

To meet the requirements of our customers, our roller bearing grinding machines are built individually with varying degrees of sophistication and different design features including special solutions. The proven assemblies of the roller bearing grinding machine feature a strict modular structure:for sequential internal, external and rim machining o...

View Details

| How much do you know about wind turbine bearing? |

In recent years, wind power in emerging markets around the world has developed rapidly. Against the backdrop of national policy support and tight energy supply, China's wind power equipment manufacturing industry has risen rapidly, and the market demand for wind power equipment has grown rapidly, which has also driven the development of wind tu...

View Details

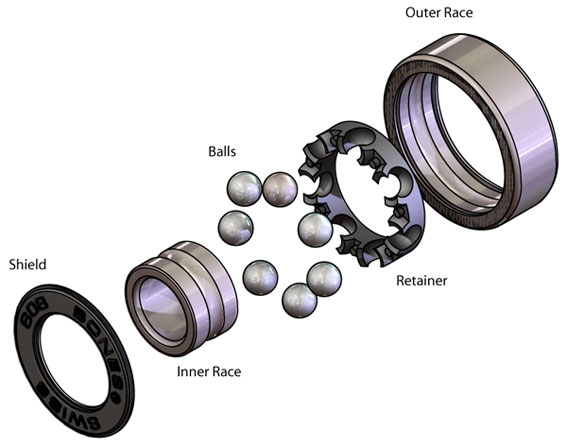

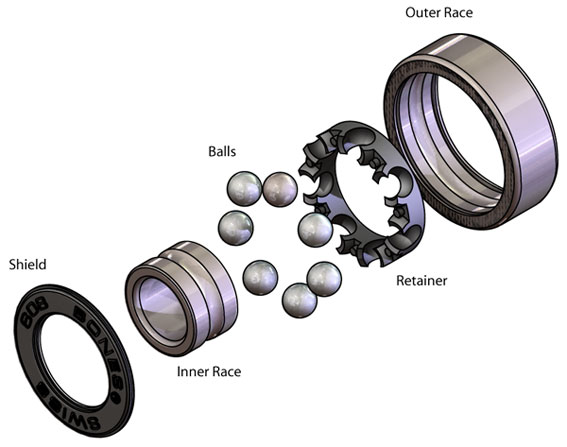

| Do you know how the steel balls fit in the rolling bearings? |

Bearings are an important part of mechanical equipment, which can not operate without bearings. However, many people do not have a deep understanding of the production process of bearings. For example, do you know how the steel balls fit in the rolling bearings? The principle is very simple.Rolling bearings are generally composed of beari...

View Details