Home > sealed-bearings

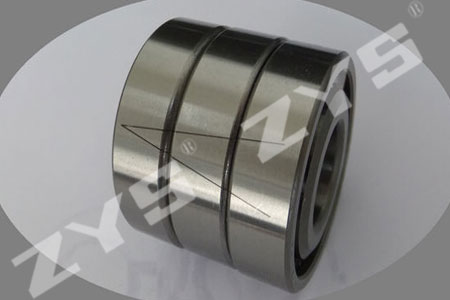

Sealed Bearings

Related

"Sealed Bearings"

ProductsRelated

"Sealed Bearings"

Blog| The role of bearings in CNC turntables |

CNC turntable is an important tool for our machining and production. As the top rank manufacturer of bearing, today we will discuss the role of bearings in CNC turntables.Bearings, as the core&nb...

View Details

| What is spindle bearing? |

Spindle bearings are a special type of single row angular contact ball bearings. They can absorb radial forces as well as axial and combined forces and are suitable for highest requirements of guiding and running accuracy, rigidity, increase in speed and decrease in friction due to their very limited tolerances.There are five types of bearings comm...

View Details

| zys machine tool bearing |

zys Bearings specializes in providing our machine tool customers with the highest quality bearings and machine tool components - fast, to eliminate costly downtime and reduce your overall maintenance costs.machine tool bearing.http://www.zys-bearing.com/special-bearing/...

View Details

| tilting pad journal bearing |

Tilting-pad thrust-journal bearing, thrust journal bearing, tilting pad bearing, journal bearingThe tilting-pad thrust journal bearings can support radial load and axial load. The tilting pad bearing can form the stable hydrodynamic lubrication oil film in the radial direction and axial direction. Tilting-pad thrust-journal bearing&n...

View Details

| ZYS bearing |

ZYS provides high quality bearing products and professional bearing solutions for users in the fields of aerospace, machine tool, wind power, metallurgy, automobile and rail transportation, construction machinery, etc. ZYS can perform batch production of various bearing products with inner diameter of 0.6mm to outer diameter of 6.8m. In addition to...

View Details

| The difference between radial thrust ball bearings and thrust angular contact ball bearings |

In use, neither radial thrust ball bearings nor thrust ball bearings can bear radial force, while thrust angular contact ball bearings can bear radial force and axial force at the same time. ...

View Details